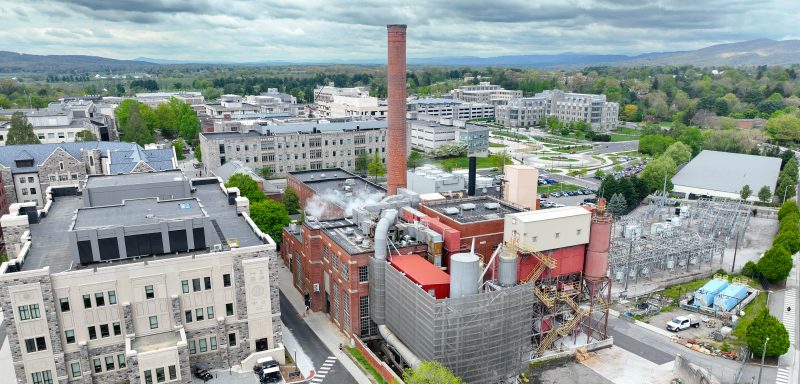

Virginia Tech Power Plant

Distinguished by a towering 180-foot-high radial brick smokestack, one of the least-known and seldomly visited places on campus plays an integral role in the university's infrastructure.

The Power Plant generates an annual steam output greater than 943 billion BTUs (British thermal units, one of which is approximately the heat produced by burning a single wooden match) and provides campus buildings with a portion of their heat, hot water, and electricity needs.

Commissioned in 1975, the 6,250-kilowatt, 12,470-volt steam-turbine-powered generator utilizes 800 degree F steam at 600 pounds per square inch from the plants boilers and distributes the lower pressure steam to an underground tunnel network. The turbine produces nearly 27 million kilowatt-hours of electricity annually.

At the heart of the plant are six boilers, each outfitted with superheaters and rated at 80,000 or 100,000 pounds of steam per hour. Four of the current boilers were installed prior to 1970, a fifth was added in 1997 and the most recent boiler was added in 2021 to meet growing demand. The boilers produce steam at 600 pounds per square inch and up to 825 degrees F.

Nearly 90 percent of campus buildings are connected to the plant through an extensive network of underground tunnels. More than six miles of steam lines and piping provide heat to more than 6.8 million square feet of campus buildings. Only personnel with confined-spaces training are permitted to enter the tunnel system.

- Inaccessible tunnel: 2.76 miles of tunnel, 11.07 miles of piping

- Direct-bury piping (in the ground): 3.78 miles

- Accessible tunnel: 2.2 miles of tunnel, 12.27 miles of piping

85-90 percent of the water used in the combined heat and power plant can be retrieved and reused. Before the water can be used in the boilers, it must run through de-aerators (to remove oxygen and other dissolved gasses) and polishers (for purification). The remaining 10-15 percent of water used for make-up in our plant comes from two 210 gallon per minute Reverse Osmosis Units. These units purify city water through nanofiltration membranes. To guarantee purity, the water is tested every four hours in the plant’s water lab. In a power plant, water quality control is imperative.

Today’s plant has undergone several upgrades since opening in 1901. The most noticeable is the switch to electronic control systems. The plant control room features multiple monitors that oversee various plant values and parameters. The plant is growing more technologically advanced as time passes and requires precise and accurate data collection. We have integrated Ignition, a new SCADA system in 2020 within our plant. This system is much more operator friendly than our previous system. Some other recent projects that have improved plant operation are #12 Boiler, #1 and #2 Reverse Osmosis Units, and #1, #2 and #3 High Efficiency Compressed Air Dryers.

#12 Boiler’s emissions efficiency is tracked using a PEMS (Predictive Emissions Monitoring System) which processes the input variables of the plant to evaluate and control the emissions to a desired level. #11 Boiler controls emissions using a CEMS (Continuous Emissions Monitoring System) which is calibrated daily to ensure accurate readings this boiler’s emissions. Our two coal boilers (#7 and #11) are also equipped with scrubber and baghouse systems that control particulate and acid-gas emissions. These two coal boilers have not been online since February 2020.